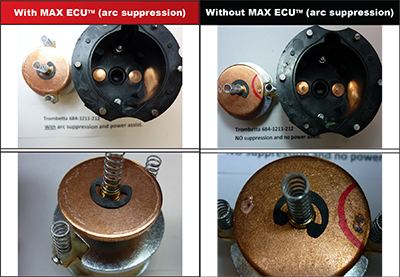

FEATURE 1 - Arc Suppression

|

Challenge

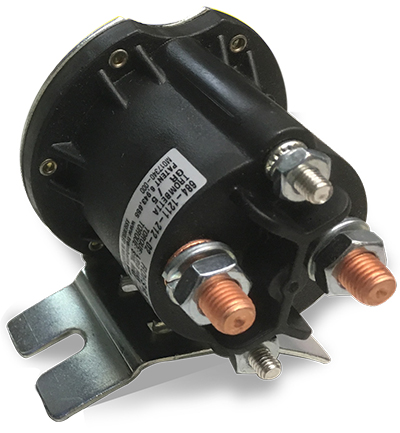

Liftgates use a high current starter solenoid to energize the hydraulic pump motor. When the liftgate switch is activated, an electrical arc occurs between the metal contacts of the starter solenoid. The arcing between the starter solenoid contacts is under high current loads and the resulting temperatures, tens of thousands of degrees, cause pitting (melting) in the metal contact surfaces. High current arcing damages the starter solenoid metal contacts resulting in shortened component life.

Solution Arc Suppression

Maxon’s Arc Suppression technology improves contact life and greatly reduces contact surface damage by absorbing the arc energy generated from the high current between the starter solenoid’s metal contacts.

FEATURE 2 - Power Assist

|

Challenge

Voltage drop from long cable lengths and motor startup loads reduces voltage needed to pull in starter solenoid contacts.

When the supply voltage to the starter solenoid coil drops below the nominal operating voltage, it weakens the electromagnetic pull force on the solenoid switch contacts. This scenario promotes solenoid switch contacts to fail by bouncing rapidly (doorbelling) creating excessive heat, welding shut and not being able to disconnect the solenoid switch contacts.

Solution Power Assist

Maxon’s Power Assist technology supplies higher voltage to the starter solenoid coil during motor startup, increasing contact pull-in forces, minimizing doorbelling and improving the contact area.

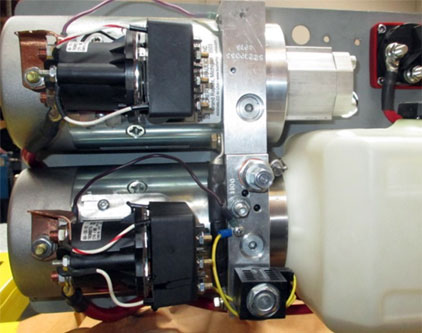

FEATURE 3 - Valve Priority

|

Challenge

Liftgate hydraulic valves are actuated by electromagnetic solenoid coils. When a liftgate hydraulic pump motor is energized, a high inrush current draw occurs causing the battery voltage to drop. Low voltage supply to the solenoid valves weakens the electromagnetic pull force to actuate the valves. This can cause the liftgate hydraulic system to fail or function improperly.

Solution

Maxon’s Valve Priority allows all hydraulic solenoid valve coils to energize first before the high inrush current and low voltage supply. This allows higher voltage at the solenoid valve coil to fully actuate the valves.